D641X Pneumatic Flanged Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

product drawing

D641X Pneumatic Flanged Butterfly Valve Series

Overview

The D641X Pneumatic Flanged Butterfly Valve is a type of valve that uses compressed air as the power source. Driven by a pneumatic actuator, the valve disc performs a 90° rotary motion to achieve rapid on-off operation or proportional control of the pipeline medium. This valve utilizes a flanged connection type, securely fastened to the pipeline flange via bolts for reliable connection. Its core transmission mechanism directly transfers the linear or rotary output torque from the pneumatic actuator to the valve stem through connecting components, driving the valve stem and the attached disc to rotate precisely within the valve body cavity. The sealing surface of the disc is typically lined with elastic materials such as rubber, forming an interference fit with the metal or non-metal seat inside the valve body to achieve bi-directional soft sealing. The D641X Pneumatic Butterfly Valve features rapid actuation, convenient control, and high integration capability for remote and automated operations. It is widely used in industrial automation control systems across sectors such as petroleum, chemical, power, metallurgy, and environmental protection.

Features

1、Pneumatic Rapid Actuation:

Utilizes single-acting or double-acting pneumatic actuators driven by compressed air, enabling swift opening and closing (typically within seconds). It allows for centralized remote control or integration with automated systems, offering highly responsive operation.

2、Stable Flanged Connection:

Designed with standard flanged ends, the valve body ensures high connection strength and excellent sealing performance. It facilitates easy installation and alignment within piping systems, making it suitable for medium- to high-pressure applications.

3、Superior Sealing Performance:

The valve disc seal is made of high-quality materials such as EPDM, NBR, or FKM rubber, providing excellent elasticity, wear resistance, and corrosion resistance. Tightly fitted with the valve seat, it ensures bidirectional zero-leakage or low-leakage sealing.

4、Low Flow Resistance and Energy Efficiency:

When fully open, the disc thickness is the only obstruction in the flow path, resulting in minimal flow resistance. This effectively reduces pressure loss in the piping system and contributes to energy savings.

5、Compact and Lightweight Design:

Compared to gate valves and globe valves of the same nominal diameter, this valve features a shorter face-to-face length and lighter overall weight. Its compact design saves space and simplifies installation and maintenance.

6、Corrosion Resistance and Long Service Life:

The valve body can be treated internally and externally with epoxy coating, galvanization, or plastic lining for enhanced corrosion protection. Key components such as the valve stem and disc are made of stainless steel or alloy steel, ensuring durability and suitability for various corrosive media and harsh environments.

7、Versatile Control Options:

Can be equipped with accessories such as solenoid valves, limit switches, positioners, and filter regulators. This enables on-off control or continuous intelligent proportional regulation to meet precise flow control requirements.

8、Easy and Cost-Effective Maintenance:

Designed with modularity, key sealing components can be replaced easily and economically. Some structural designs even allow for in-line replacement of seat seals without removing the valve from the pipeline.

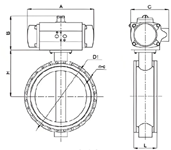

Dimensions & constructral diagram

D641X Pneumatic Flanged Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Part Name | Material |

|---|---|

| Pneumatic Actuator | Aluminum Alloy (cylinder body) + Carbon Steel (accessories) |

| Valve Stem | Stainless Steel (304) |

| Disc / Butterfly Disc | Ductile Iron (rubber-coated surface) |

| Sealing Component / Element | Rubber (Nitrile Butadiene Rubber NBR / Ethylene Propylene Diene Monomer EPDM) |

| Valve Seat | Rubber (matching the material of the Seal Kit) |

| Bolt / Nut | Carbon Steel (or Stainless Steel) |

| Valve Body | Ductile Iron |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | MPa |

| Strength Test Pressure | 2.4 | MPa |

| Sealing Test Pressure | 1.76 | MPa |

| Applicable Temperature | ≤80 | ℃ |

The main external and connection dimensions

| Inch (in) | DN (mm) | Size (mm) | Actuator Dimensions (mm) | |||||

|---|---|---|---|---|---|---|---|---|

| H | L | D1 | n-d | A | B | C | ||

| 2" | 50 | 120 | 108 | 125 | 4-18 | 163 | 96 | 76 |

| 2-1/2" | 65 | 130 | 112 | 145 | 4-18 | 195 | 115 | 91 |

| 3" | 80 | 145 | 114 | 160 | 8-18 | 195 | 115 | 91 |

| 4" | 100 | 156 | 127 | 180 | 8-18 | 217 | 137 | 11 |

| 5" | 125 | 170 | 140 | 210 | 8-18 | 258 | 147 | 122 |

| 6" | 150 | 188 | 140 | 240 | 8-22 | 299 | 165 | 136 |

| 8" | 200 | 205 | 152 | 295 | 8-22/12-22 | 349 | 182 | 153 |

| 10" | 250 | 235 | 165 | 350/355 | 12-22/12-26 | 397 | 199 | 173 |

| 12" | 300 | 280 | 178 | 400/410 | 12-22/12-26 | 473 | 221 | 192 |

| 14" | 350 | 330 | 190 | 460/470 | 16-22/16-26 | 560 | 249 | 213 |

| 16" | 400 | 320 | 216 | 515/525 | 16-26/16-30 | 601 | 280 | 243 |

| 18" | 450 | 400 | 222 | 565/585 | 20-26/20-30 | 738 | 358 | 356 |

| 20" | 500 | 500 | 229 | 620/650 | 20-26/20-30 | 738 | 383 | 356 |

| 24" | 600 | 570 | 267 | 725/770 | 20-30/20-36 | 940 | 434 | 415 |